- Thin wall design for reaching in to recesses

- Protective sleeve for use on alloy wheels

- DIN standard design for use with a retaining pin and ring

- Chrome molybdenum for use with power tools

- Ring and pin fixing hole on the female end to secure the socket to the air gun

-

-

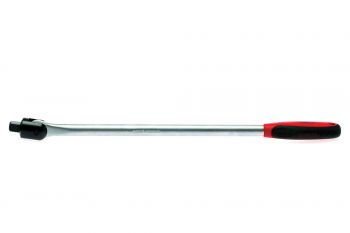

- Flexible head with ball detent retainer on the drive end for secure socket connection in high torque situations

- Constructed from durable high-quality chrome vanadium with satin finish for superior strength and control

- Ergonomic bi-material grip designed for comfort during prolonged use

- Adheres to DIN 3122F standards, offering reliable performance

-

- Flexible head with ball detent retainer on the drive end for secure socket connection in high torque situations

- Constructed from durable high-quality chrome vanadium with satin finish for superior strength and control

- Ergonomic bi-material grip designed for comfort during prolonged use

- Adheres to DIN 3122F standards, offering reliable performance

-

- Includes the most commonly used wheel nut socket sizes

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

- ANSI standard design with a ball bearing socket retainer

- Chrome molybdenum for use with power tools

- Black phosphate finish for easy identification as an impact socket accessory

-

TIG Stainless steel filler metal 308L in rods for welding austenitic stainless steels with and without molybdenum (316, 316L, 316 Ti/Nb304, 304L). Classification: AWS A5.9 : ER 316L EN ISO 14343-A: W 19 12 3 L Applications: Pipes, structures with thicknesses of 3mm or less and for penetration passes. For use with assemblies preheated to temperatures less than 400°C. Good corrosion resistance.

-

TIG Stainless steel filler metal 308L in rods for welding austenitic stainless steels with and without molybdenum (316, 316L, 316 Ti/Nb304, 304L). Classification: AWS A5.9 : ER 316L EN ISO 14343-A: W 19 12 3 L Applications: Pipes, structures with thicknesses of 3mm or less and for penetration passes. For use with assemblies preheated to temperatures less than 400°C. Good resistance to corrosion.

-

TIG Stainless steel filler metal 308L in rods for welding austenitic stainless steels without molybdenum (304, 304L, 321, 347). Classification: AWS A5.9 : ER 308L EN ISO 14343-A: W 19 9 L Applications: Pipes, structures with thin thicknesses of 3 mm or less and for penetration passes. For use with assemblies preheated to temperatures less than 350°C.